If you find this website useful, please check out my books or visit my Amazon Author page. Or even Buy Me a Coffee!

Reference Information

Reference Information

This is a repository for all sorts of workshop data and background information.

A question that is being increasingly asked across the web is 'what is a TLRT?'

The acronym TLRT was originally coined in 2019 by user @Skinnyman on the Basschat.com forum, as a way to characterise the 'reaction icons' in the popular Invision Community web forum platform.

TLRT stands for 'Those Little Reaction Thingies'.

Resembling large emojis it is possible for different sets of TLRTs to be enabled on a forum, a typical selection is 'Like' - a heart, 'Thanks' - a trophy as well as laughing, confused and sad faces.

The use of TLRT spread rapidly to other Invision Community forums, and has been used on other forum software and even Facebook,

So there you have it, and hopefully by the power of Google search, no-one need ever wonder what a TLRT is again.

Why have five TLRTs instead of a million and eleven emojis?*

In other words, they are there to add to the positive reputation of the recipient within the forum. Some are added to the Basschat Watts score, negative ones are not but give an indication, without flames, of the readers sadness or confusion over the subject post. The five TLRTs are:

![]() Thanks - positive

Thanks - positive![]() Haha - positive

Haha - positive![]() Confused - null

Confused - null![]() Sad - null

Sad - null![]() Like - positive

Like - positive

Of course these may seem limited to some users** but we all know that there is far too much choice available to people these days. Less is more, Basschat orange is the new black and moss never settles on a Basschat Watts score.

A limited number of TLRTs are allocated on a daily basis and once used, the member can not express his or her reaction until they are replenished by the forum software. Members stating that they are all spaffed out merely means that they can not add their reaction to a post today because they've used them all up by reading @skankdelvar's posts before anyone else's.

*Thanks to @Spondonbased for this valuable information

**@Teebs mostly

- Details

- Category: Reference Information

Yashica Mat medium format twin-lens reflex cameras take unfeasibly good photographs, especially on transparency film like Fujichrome Velvia 100. But tehy are getting old, which means the lubrication inside is getting thick and sticky.

There are lots of people claiming to have fixed sticky shutters on Yashica Mat twin-lens reflex cameras, but not many giving advice on how to do it.

The easy route is:

- Peel off the leather around the lenses - it will have gone hard and nasty and come off in small bits.

- Remove the four largest screws.

- Lift off the lens and shutter unit.

- Set it for f3.5 and 1/500 of a second - this is to make it easy to get it lined up when you put it back together.

- Remove five small barss screws holding the lens surround on.

- Unscrew the lower lens.

- Turn the locking screw on the daisy nut revealed by the lens 180 degrees.

- Remove the daisy nut.

- Lift off shutter cover plate (it is in two layers).

- Clean the shutter mecahnism with the solven of you choice and allow to dry thoroughly. I used carb cleaner (outdoors, of course!

- Clean everything of dust.

- Lubricate sparingly with either an incredibly light oil like sewing machine oil (not WD40!) or graphite powder.

- Do not lubricate the shutter 'leaves'.

- The button at the left of the lens opening will allow you to cock and test the shutter.

- Remember! If testing the self time the flash synch lever must be down (at X position).

- Once working reassemble in reverse order after throughly cleaning the lens to remove dust.

- Remember! Reset to 1/500 and f3.5 (fastest shutter, iris wide open). before fitting the lens shroud so the controls line up.

Now, all is working, but it looks awful without the leather front.

Download this free template to allow you to cut out a suitable piece of thin leather or vinyl (for example from an old wallet). Cut it out, trim to fit and stick in place with an impact adhesive.

Congratulations! Another wonderful old camera saved!

- Details

- Category: Reference Information

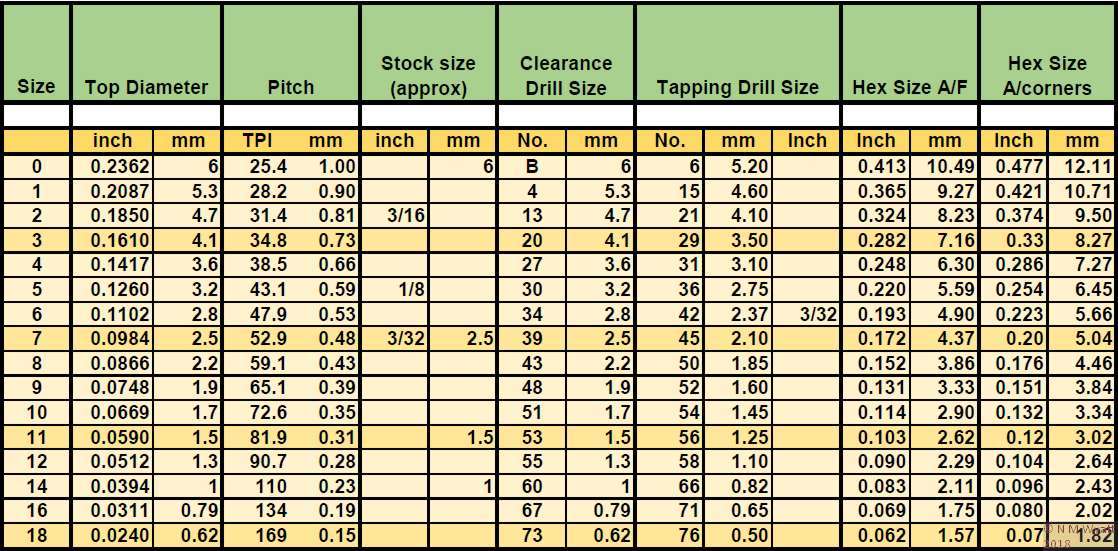

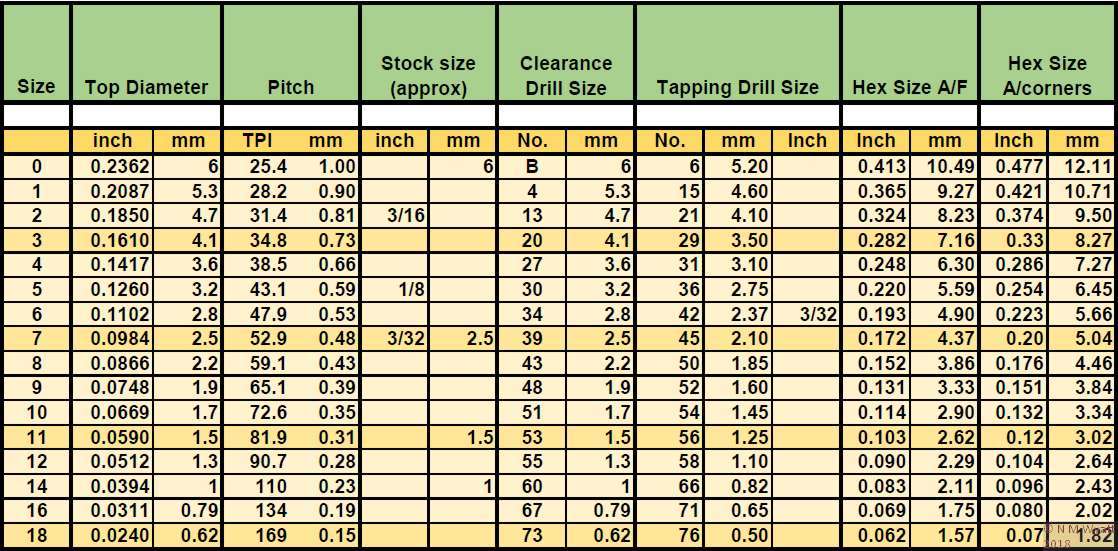

The BA (British Association) series of screw threads is a strange hybrid. Based upon a Swiss standard they are metric sizes, with the largest, 0BA, having the same nominal diameter of 6.0mm and pitch of 1.0mm as the standard M6 metric coarse thread. The main difference is that the BA thread form uses an unusual 47-degree angle, so it is slightly deeper and sharper than both the ISO metric threads (which use 60 degrees) and Whitworth (at 55 degrees). The threads sizes are, however, defined in inches in the British Standard.

So, why does this thread form continue, and why is it so popular with model engineers? Two good reasons - the first is it has the wonderfully useful property of having sizes in closely spaced, geometrically regular sizes. 1BA is 0.9 times the size of 0BA, 2BA is 0.9 times the size of 1BA and so on. The differences are small enough that there is always an ideal BA size when you need a small thread, with no awkward gaps - such as the big step between M3 and M4. This is good for scale modellers as with 10% change between each size, you can always find a thread within 5% of scale size, and such a small difference is negligible for most purposes. Larger BA nuts and screws (often down to 8BA) can also supplied with 'one size smaller' hexagons, so 2BA may be made from 3BA hexagon stock, for example. These fixings generally have a better scale appearance - but check, some very old machines used much larger hex nuts in proportion to the thread!

It also means that some BA sizes conveniently fit on some stock material sizes - very handy! 0BA on 6mm, 2BA on 3/16", 5BA on 1/8 and 7BA on 3/32" or 2.5mm, for example.

Finally, the BA fixings generally have a finer thread pitch than similar metric threads, another factor that makes them look better on models.

<Homer Simpson>"Is there nothing BA can't screw?"</Homer Simpson>

Here's a handy chart with all the really important figures for BA fixings. Enjoy!

- Details

- Category: Reference Information

If you look at the data on BA screws, you will see that the base size of 0BA is 6mm diameter and 1mm pitch, yet the sizes are usually quoted in thousandths of an inch. Why?

The answer is the good, honest pragmatism of the British Association for the Advancement of Science's BA Small Screws Committee, back in 1882. The committee included no less a person that Sir Joseph Whitworth (who was lavishly praised in their reports for his work on standardisation!) Bearing in mind that a 'mil' is a thousandth of an inch they reported:

The question of the introduction of the metrical system occupied the serious consideration of the committee, but, considering the fact that it is not generally adopted in engineering or manufacture in England, and that it is as yet little understood by our workmen, it was thought better to suggest no change in this direction. The committee is not insensible to the simplicity of the metrical system and to its possible universality, nor to the fact of its gradual introduction in scientific circles, but while the manufacturing interests are still wedded to the British inch, and its multiples and sub-multiples, and while the British legal standard of length is still the yard, the Committee has felt it impossible to suggest a change which has little chance of adoption, and which might jeopardise the introduction of that with which they are more concerned—viz., a uniform screw-thread.

Hence it was determined that the unit of length taken should be the ‘mil,’ and that the decimal system should be adopted for expressing dimensions.

In short, they knew that if they used a metric standard it would just confuse British manufacturers used to working in inches, and they would be ignored!

The Committee continued to sit (although an administrative hiccough meant they hadn't been sanctioned to do so!) and gave considerable thought to further issues for their second report. They made one change to the continental standards, making the rounding of root and crest of the thread the same. Their other change was to specify all the threads in millimetres to two significant places! They did, however, offer conversions to inches for convenience:

That in view of the desirability of securing a system of small screws—international in its character—English manufacturers of screws, screw-plates, &c., adopt the exact pitches given in millimetres in [the table], which, as we explained [earlier], can, if required, be originated on an English lathe.

So, the list of BA thread sizes is reached on the basis of a list of sizes, each 0.9 times the size of the previous, starting at 6.00 millimetres. This list is then rounded to the nearest hundredth of a millimetre, equivalents in 'mils' or thousandths of an inch are approximate. We have to face the truth, British Association threads are well and truly metric.

Vive la Difference!

A rather wonderful, if swarfy, BA die of good vintage

A rather wonderful, if swarfy, BA die of good vintage

- Details

- Category: Reference Information

The British Association series of fixings may seem a strange and eclectic set of screw thread series, but they are actually really well worked out. Based on Swiss practice, but defined in the UK, the basic thread size is 0BA which is the same diameter and pitch (6mm and 1mm) as M6 screws. The different thread angle (47.5 degrees) means that although M6 and 0BA may fit together, the two threads don't engage properly.

As you move to smaller BA sizes, each increase in number is a reduction in size of 0.9 times. This means that the BA series offers ideally spaced fixings throughout the range with no awkward gaps. In fact just using even-numbered sizes is sufficient for most practical purposes and many would argue it gives a better range than comparable metric sizes. The odd-numbered sizes can be useful to get the biggest possible fixing in a small space.

My Grandfather's set of LAL BA Taps and Dies, still in use today.

BA fixings are a real boon for scale modellers, as the 0.9 ratio means you can always find a screw thread within about 5% of scale size, a difference unlikely to be noticed. For modelling scale fixings, especially post 1940s Whitworth ones it is customary to use screws and nuts made with 'one size smaller' BA hex, although standard BA hex sizes do match proportions well with many older (e.g. Victorian) examples.

A final note, as raw hex stock in BA sizes becomes more difficult to obtain, BA fixings may be supplied with hex from a near metric equivalent. The difference is usually so small that it goes unnoticed, unless two sizes of hex are used side by side.

BA Fixings Data Chart

- Details

- Category: Reference Information