Making the QCTP Block

This article show you how to make this Quick Change Toolpost which suits popular 7x12 and similar mini-lathes

The design is also suitable for almost any lathe of about 3 1/2" or 80mm centre height including Myford ML7 and Super 7 lathes.

You can download a free set of plans for the QCTP design with this link.

Whenever you tackle a complex turning task, one that involves repeating a series of operations on several parts, you may get frustrated by the limitations of the standard 4-position toolholder.

Four Position Toolholder

One problem is that, in practice, these normally only holds two tools conveniently. One solution is a Quick Change Tool Post, a variety of suitable ‘QCTP’s can be bought for mini lathes, but once you factor in the need for a good set of compatible toolholders (I have twelve, and could usefully have twice as many) the cost starts to spiral. An alternative is to make one yourself, and although this is not a raw beginner’s project, it is a good test of your skills once you are more familiar with the lathe. Note that although it can be made entirely using the lathe itself, milling the dovetails and tool holder slots is much easier if you have access to a milling machine. This is also a project which is made much easier if you have a metal cutting power saw of some kind. There is a lot of quite large section mild steel that needs cutting, and if you have to do this by hand, be prepared for some hard work.

The design is based on the Nakamura Toolpost, but this has a couple of limitations – the piston does not retract automatically and has to be pushed back; it only takes one toolholder; and it overhangs the topslide excessively. The changes here to address the last two of these issues by adding a second dovetail and piston and reducing the overall dimensions of the block. Internal springs cause the pistons to be self-retracting. The toolholder offers ease of use and rigidity, the handle requiring very little pressure to fully lock the holders. Dimensions given allow the sliding and rotating parts to move freely without excessive slop, and will help make sure the dovetail fits are right. In practice, use your experience and judgement bearing in mind the function of each pair of mating surfaces.

You can download a full set of plans for the toolholder here.

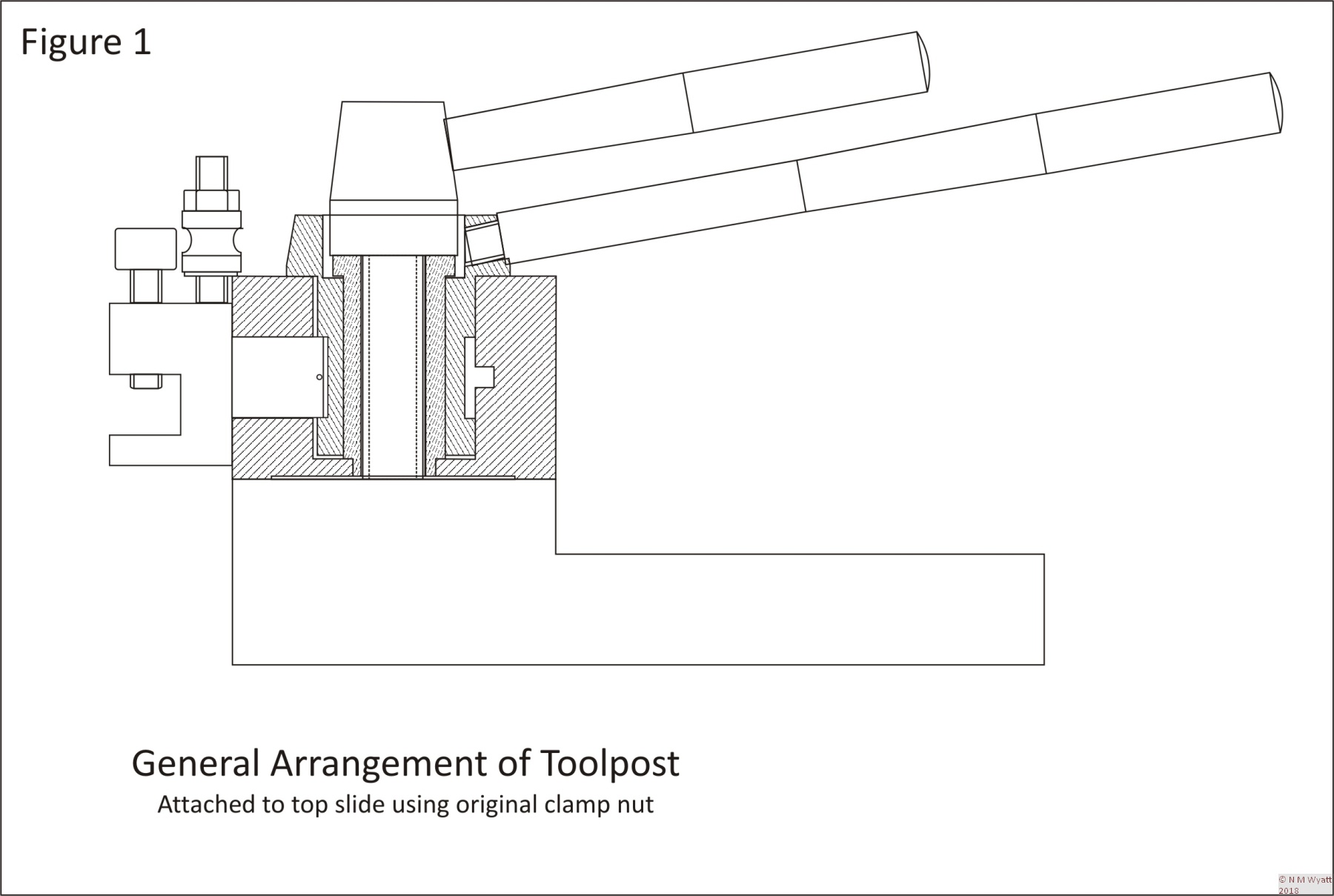

The operating principle of the toolpost may not be immediately obvious from the general arrangement (figure 1).

General Arrangement of Quick Change Toolpost

The main body (block) of the toolpost has a circular cavity in which a cylindrical cam is fitted. The cam has a hole through the middle allowing a free central pillar to be threaded onto the toolpost stud and clamped by the original lathe clamping nut. The pillar is sized to clamp only the block, so the cam, with its own handle, is free to rotate. The eccentric portion of the cam bears on two brass ‘pistons’, one in each of the dovetails on the block. Toolholders fit on these dovetails, and when the handle is used to turn the cam, it pushes on the pistons, locking the toolholders in place. Each toolholder has a setting button on top, which allows it to be removed and replaced at exactly the same height. To make using the toolpost easier, wire springs in the pistons engage with a groove in the toolpost block, so that when the cam is turned back, the pistons release automatically.

Materials

For the toolpost itself:

- Just over 1 1/4” length of 2” square bright drawn mild steel (BDMS) or continuous cast iron for Toolpost Block

- About 1 1/2” of 1 1/2” diameter round BDMS for the cam

- 2” of 5/8” diameter brass for the pistons

- 3” of springy wire about 1mm/0.04” diameter for piston springs

- 6” if 3/8” diameter BDMS for the handle

- 1 1/4” of 3/4” diameter BDMS for the pillar

For each standard or boring bar toolholder:

- 2” of 1” square BDMS

- 1 1/2” of M5 studding

- 4 M5 cap head screws

- 2” of 1/2” diameter brass

- 1 M5 nut

Note that, in practice you should allow a cutting allowance e.g. 20” of bar will make nine full-length toolholders and leave a useful offcut. Other types of toolholder may need different materials.

A final thought, for small lathes, toolposts are often made from high-strength aluminium alloys. You may wish to use such a material for the block and toolholders, especially if you have a way to get them hard anodised.

Construction

I don’t propose to give every detail of construction, but the nature of some of the parts is such that I feel it is useful to at least give a recommended approach that minimises the number of setups require. This is not exactly how I made my holder, but it is how I would make a second.

Toolpost Block

The toolpost block is made from a single piece of 2” square mild or medium carbon steel. The former is easier to machine, the latter should last a lifetime. Mount it in a 4 jaw chuck, getting it a central as possible, face off the bottom to a good finish and turn the shallow rebate. The rebate is essential to ensure the outer edges of the block make contact with the topslide, maximising grip. Now reverse the block in the chuck and face it to exact length. Drill the central hole in 2 or 3 stages. Use this hole to start your preferred boring tool to make the central 1” diameter recess, noting that it should be parallel sided with a well finished flat base. Now with a suitable recessing tool, put in the internal 1/8” groove – the centre line of the piston holes will align with this groove, so take care to get it in the right place.

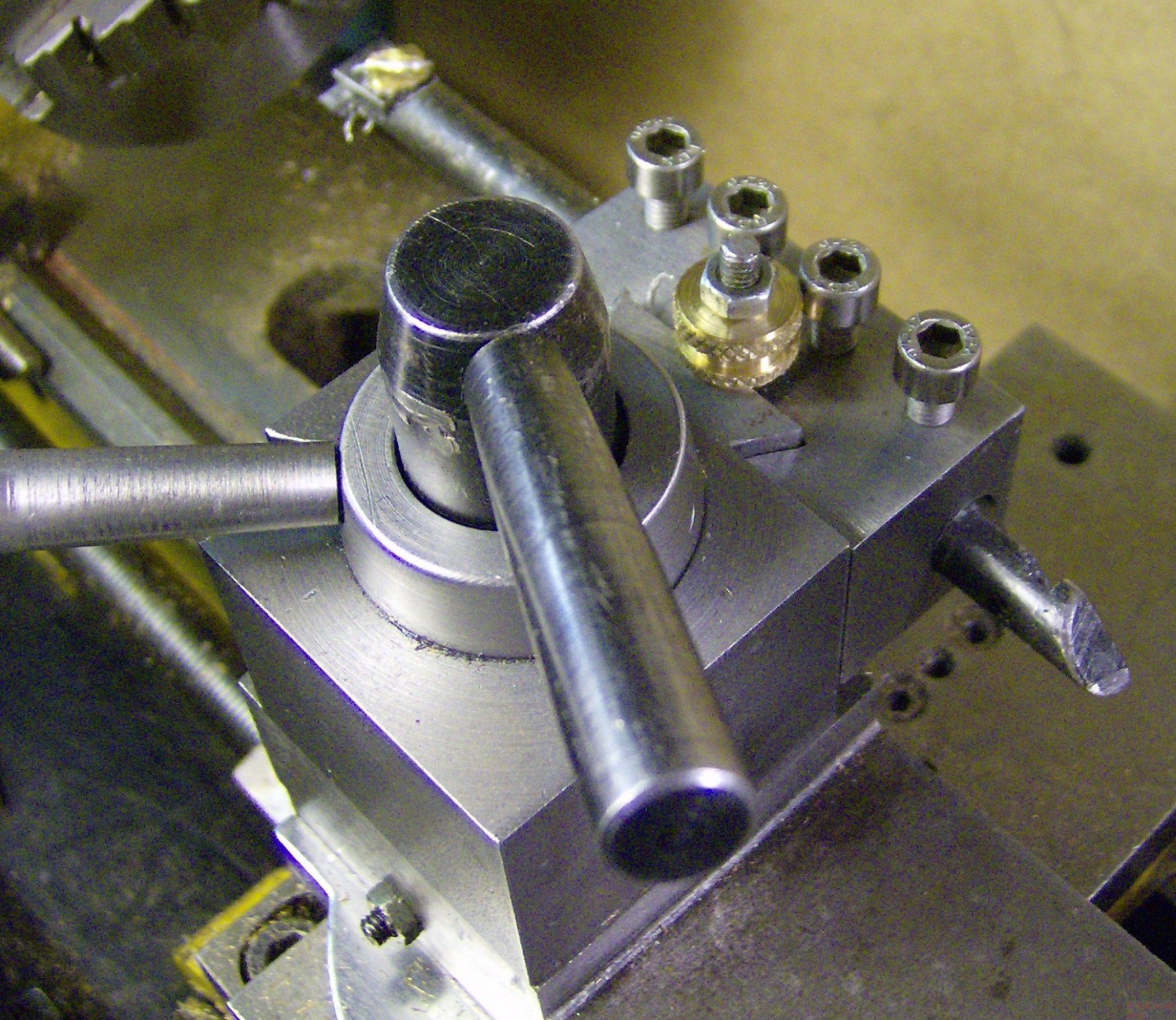

The main block at the heart of the QCTP

Remove the block and mark out two faces with centres for the two piston bores. Return the block to the 4-jaw to bore and counterbore each piston hole in turn. You can drill these holes but if you are not sure of the finish your 1/2” drill leaves, then use a reamer or finish them by boring. The same recessing tool you used to cut the internal groove can be used to cut the counterbores. The depth of the counterbores is 1/8” at the shallowest point. This is to allow the rim on the pistons to move fully out of the way when fitting the cam.

We now need to cut the two dovetails. Here is the method I used, which relies on the block being a reasonably accurate 2” across. Mount the block upright in a milling vice, and zero a decent sized slot drill to the top and side of the block. Cutting a full 0.250” depth take successive cuts towards the centre until you have removed a step 0.500” long. Repeat from the other side of the block, and you should be left with a central raised area an inch wide with the piston bore at its centre. Do the same to the face with the other piston bore and check both raised steps are the same width.

To finish the dovetails, use a dovetail cutter, set to cut 0.250” down from the top surface, on one side of a step cutting in stages until the small ‘witness’ between the top face and the sloping face just disappears. Zero your DRO or handwheel index at this point. Now move to the opposite face of the step and machine the other dovetail the same way, noting the final distance reading. When you machine the second pair of dovetails start the same way, zeroing the index/DRO when you finish the first dovetail. When you machine the opposite face of this second dovetail, make sure your finishing cut is at the distance you recorded at the end of the first one. The two pairs of dovetails will now match perfectly, ensuring all your tool holders can be fitted to either of them.

An additional touch is to mill a small pocket on the underside of the block for the catch on the topslide, allowing the block to be reset correctly more rapidly. To add this, scribe a line exactly on the mid-point of the underside of the block. Now mount the block in the mill inclined backwards at 10° from the vertical. Line up a 1/2” (or similar) end mill with the scribed line and mill the pocket about 1/8” deep. The pocket should be behind the ‘front’ dovetail and be milled with the side dovetail facing down. If you are unsure – copy the pockets on the original four-way toolpost. Though I have done this on my toolpost, I am not sure how useful it is – the setting is not particularly repeatable, and unlike the four-way toolpost, you should rarely need to turn the quick release version.

Tidy up the block with fine file to remove any burrs and break the ‘arris’ on machined edges. You can draw file and then use emery paper to make the unmachined faces look a bit brighter. It is up to you if you want to paint any surfaces of the block.

Toolpost Clamp Pillar

This item (figure 3) takes the full force of the toolpost clamping nut and transfers it to the bottom of the block. If possible make it of a medium carbon steel such as EN24T, rather than plain mild steel.

The pillar is drilled clearance for the toolpost stud and is a light push fit in the hole left at the bottom of the recess in the block. Make sure the step on the end is slightly shorter than the thickness of the base of the block, so that when the toolpost clamp is tightened up it grips the block firmly in place. The length of the middle section of the pillar is a critical dimension – it should be the same as the depth of the central recess in the block. Note that this toolpost uses the existing lathe toolpost clamp (although you could make your own copy if you wish).

It is important that the clamp-screw handle points in the right direction when it is tightened up, so start by making the pillar slightly tall. If the handle points the wrong way you can face off the end a little (0.3mm off the end will allow the clamp handle to turn about 90° further).

Cam

The cam is a deceptively simple item. There is little worth in making it from medium carbon steel as the wearing surfaces are large and the impact of minor wear on the action of the cam would be negligible. The reference point for all dimensions is its top. The thickness of the upper part should be about 0.002” greater than the depth of the recess in the top – this ensures that when the pillar is locked in place by the toolpost clamp the cam will turn freely without perceptible shake.

I suggest this order or operations: In the 3-jaw chuck face off one end of the bar and drill and bore it 0.760” or greater – a very loose fit on the pillar. Now turn the outer diameter of the top part and counterbore the recess 0.377” deep. Reverse the bar and trim it to length - 1.490”. Turn the bottom section to a close push fit in the toolpost body, perhaps 0.998” and so that the length leaves the top part exactly 0.375” thick (i.e. two thou less than the depth of the recess). Move the bar to the 4-jaw chuck and offset it by 3/64” (this is not a critical dimension) and turn the offset section noting that its top and bottom edges should match with the piston holes in the block.

Now, return the bar to the three jaw in order to turn the 10-degree taper on the top section (photo 5). Do not make the tapped hole for the handle until later, or like me you will end up with an extra hole.

Pistons

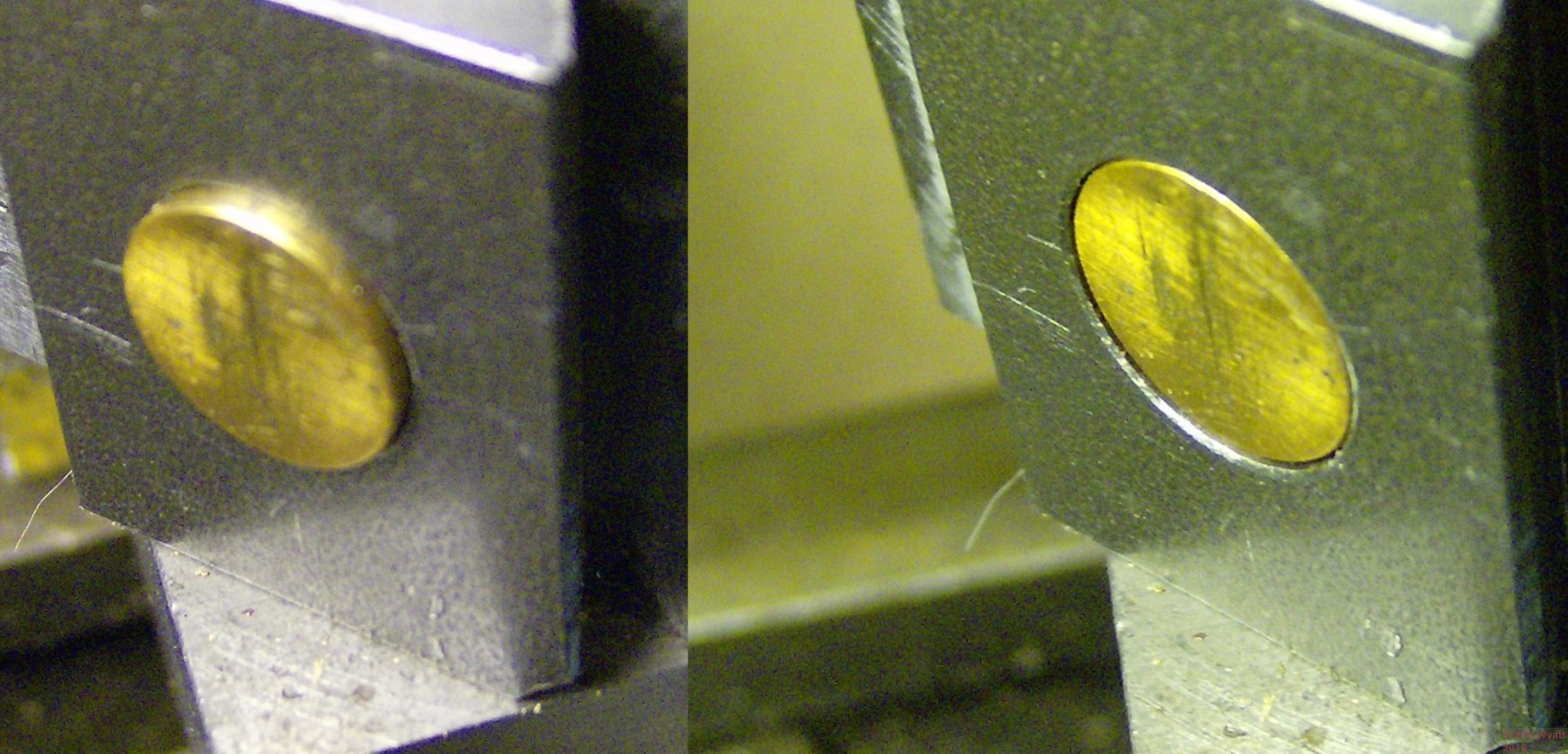

The pistons (figure 5) can be turned from 5/8” or 15mm brass rod if 9/16” is not available. Turn the main part of the pistons to a sliding fit in the block, making sure there is a good smooth finish. The flanges take no load, they only need to be big enough to stop the pistons falling right through the holes.

So you can have sprung pistons that withdraw automatically, you need to drill No.58 (this size is a loose fit for a 1mm diameter spring wire) right through. Perfection isn’t essential, but you need to be fairly accurate with this hole. A good centre pop will ensure the drill doesn’t skid, clamp the vice to the drill table and once the hole is started check the drill isn’t bending off course. Don’t forget to clear the flutes regularly – small drills clog rapidly. You now need to file flats on the piston flanges so they don’t foul the outer diameter of the cam. These can be done by eye, but ensure they are parallel with the cross-drilled hole.

The QCTP locking pistons

Try the pistons in their bores with the cam in place and make sure they are both free moving and don’t interfere with each other, aside from the desired in-out action. The pistons should be just below the surface of the dovetail when fully retracted.

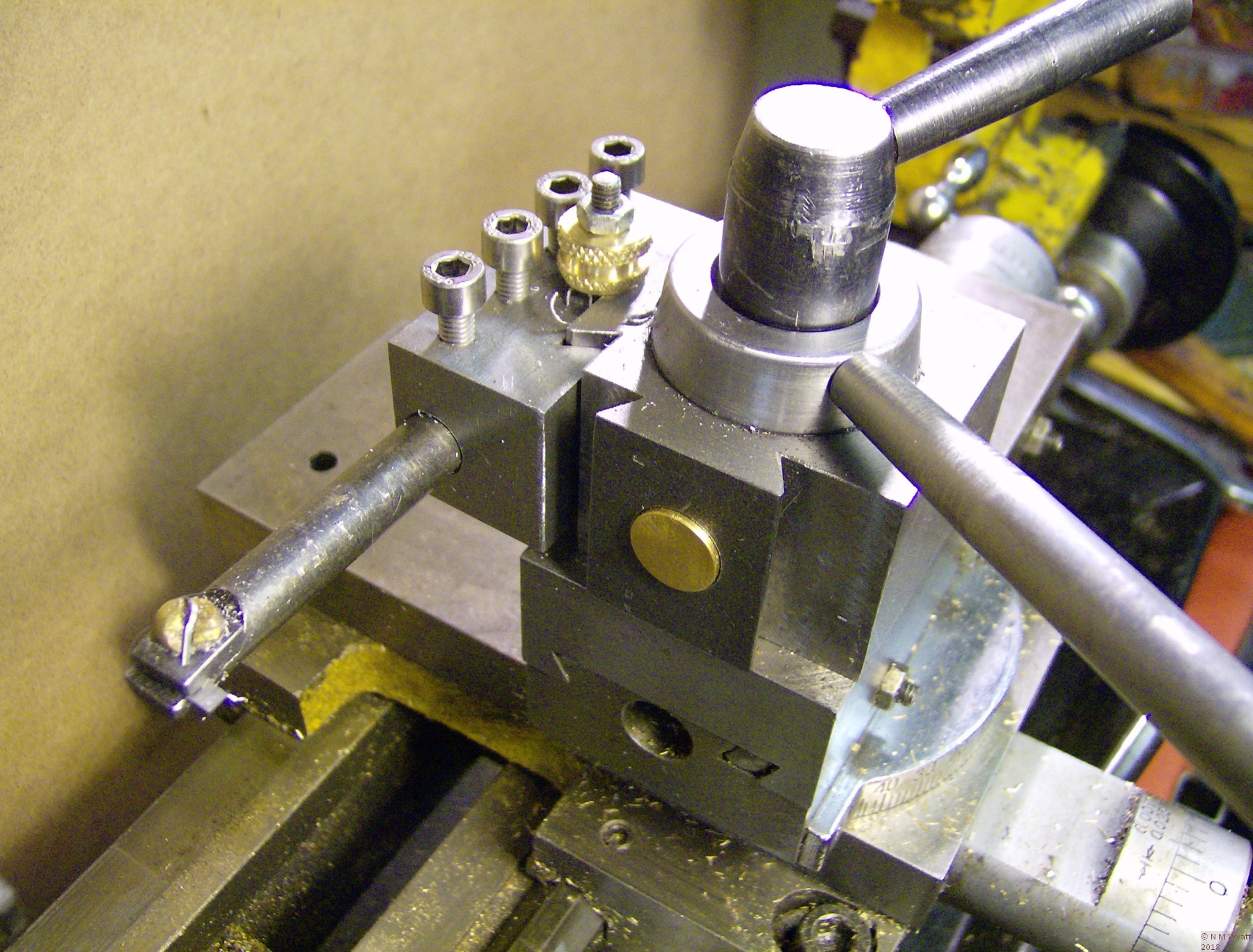

Before final assembly, you should do a trial fitting of a toolholder on each dovetail in turn, to see what is the best position for the handle. At this point I suggest you make the first toolholder, at least as far as cutting the dovetail on the back of a toolholder blank, but I shall finish the description of making the toolpost before moving on to the holders.

Choose the position of the handles so that they do not get in the way of fitting the toolholders when the relevant piston is retracted, and about a 90-degree turn locks the toolholder without the handle getting in the way of lathe operation. Mark the best position for the hole. Do not assume the best position without this test, or, like me, you will end up with an extra hole. If this happens, you can blank the hole with a short stub of M6 thread which will virtually disappear if carefully filed and smoothed with emery paper.

Properly fitted the handles will not interfere with each other

The hole for the handle should ideally be drilled with the cam in an angle vice at 10 degrees, but if you don’t have one, just raising one end of a normal drill vice on a block will suffice if due care is taken. Check the handle will be in the right place by fitting an ordinary M6 bolt and doing a dry run before fitting the springs.

On final assembly, fit the 1 1/14” lengths of spring wire in the cross holes. Make sure everything is clean and free of swarf, then lightly grease the pistons and fit them into their bores, aligning the springs with the groove in the block. I suggest using molybdenum-loaded or teflon grease as my experience is that these work well for parts that do not continually rotate. Grease the cam and line up the bevels on its base with the pistons, and it should be possible to insert the cam with a light click as it goes home. It will now be very difficult to take the cam back out and disassemble the toolpost. If you need to, drill and tap the pistons, say 8BA, for screws that can be used to pull them forwards so the cam can retract. The flanges will stop the pistons rotating and allow this to be done, or if you are super-cautious you can make these holes prior to parting the pistons off.

Handle

The toolpost is now complete, aside from the handle. This is simply made from a length of 3/8” bar, with an M6 thread on one end. The tapered section should be turned at about 1° (2° included angle) to match the standard mini-lathe handles. The handle can now be screwed into place, the pillar popped into the centre hole of the cam, and the toolpost fitted to the lathe.

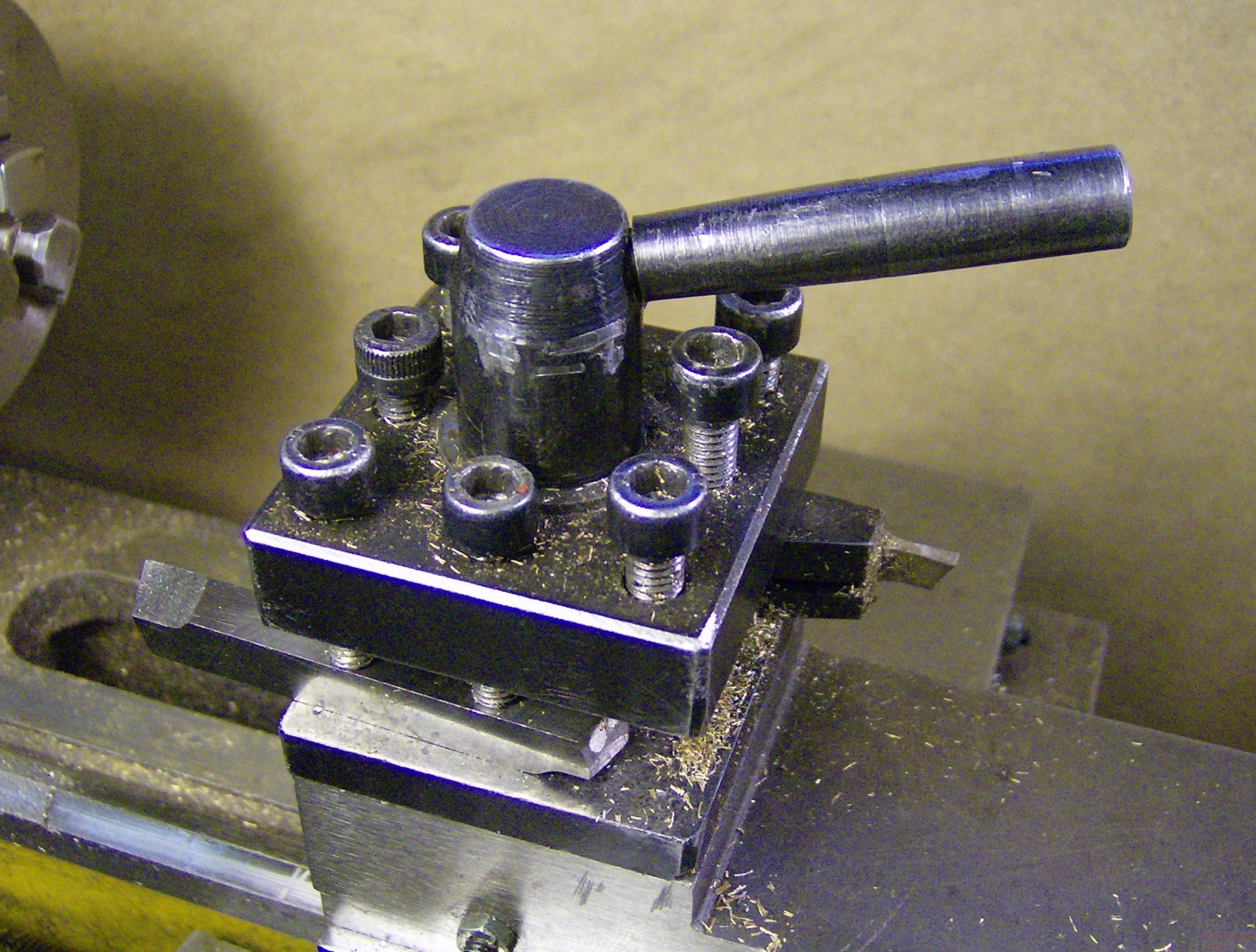

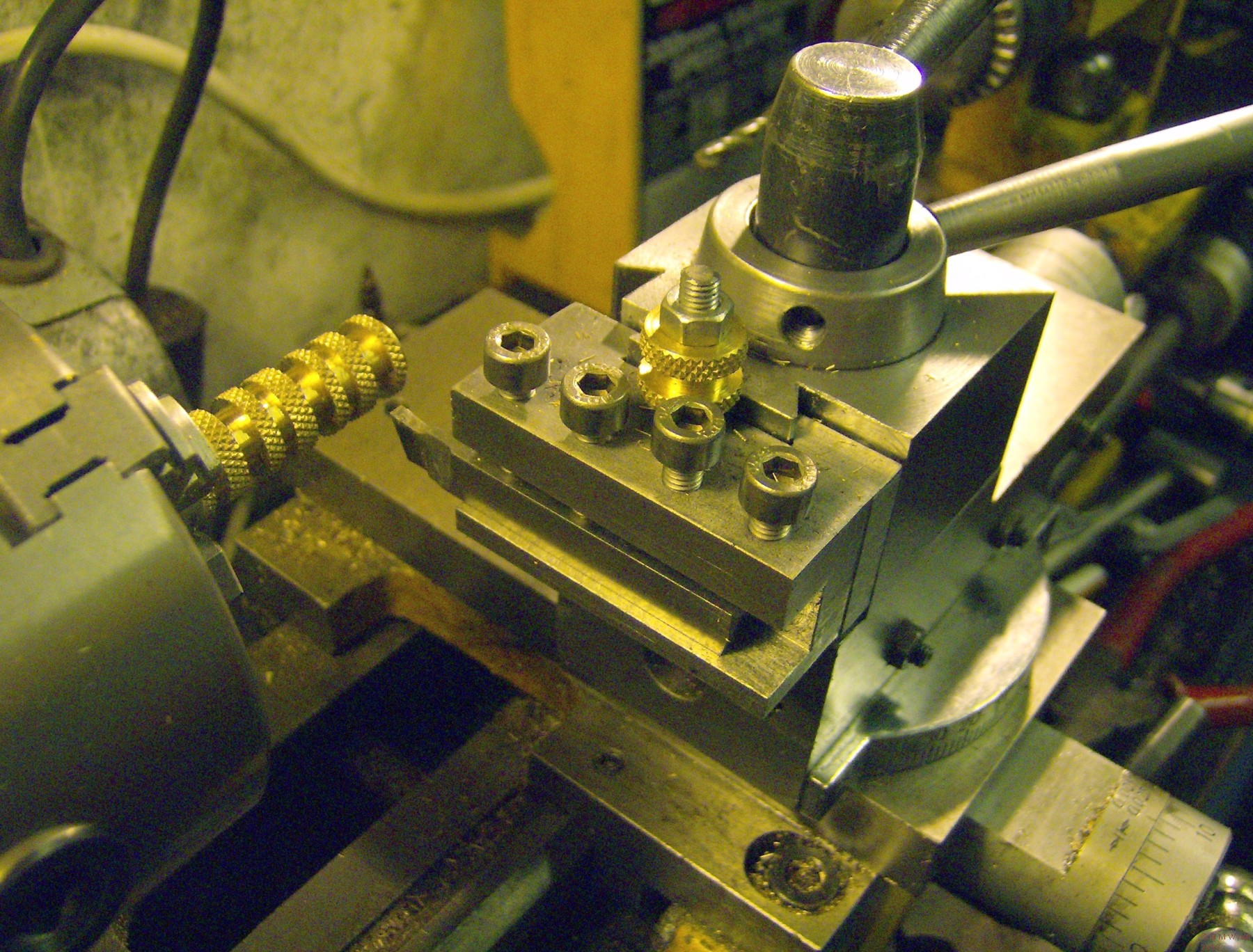

The QCTP in use

Part 2 shows you how to make a set of toolholders

You can download a free set of plans for the QCTP design with this link.