The gear cover of the CL300M and other mini lathes is held in place by two bolts. Continually removing and replacing these bolts is tedious, yet the temptation to operate the lathe with the cover removed should be resisted for (hopefully) obvious reasons. In past issues of MEW two solutions have been offered – both involved replacing the M5 cap screws with an easier to release alternative. However, these ideas still mean having to undo screws, and there remains the risk of losing a fastener in the swarf or under the bench!

May I suggest an alternative approach? It is literally a ten-minute job to perform an instant-release modification.

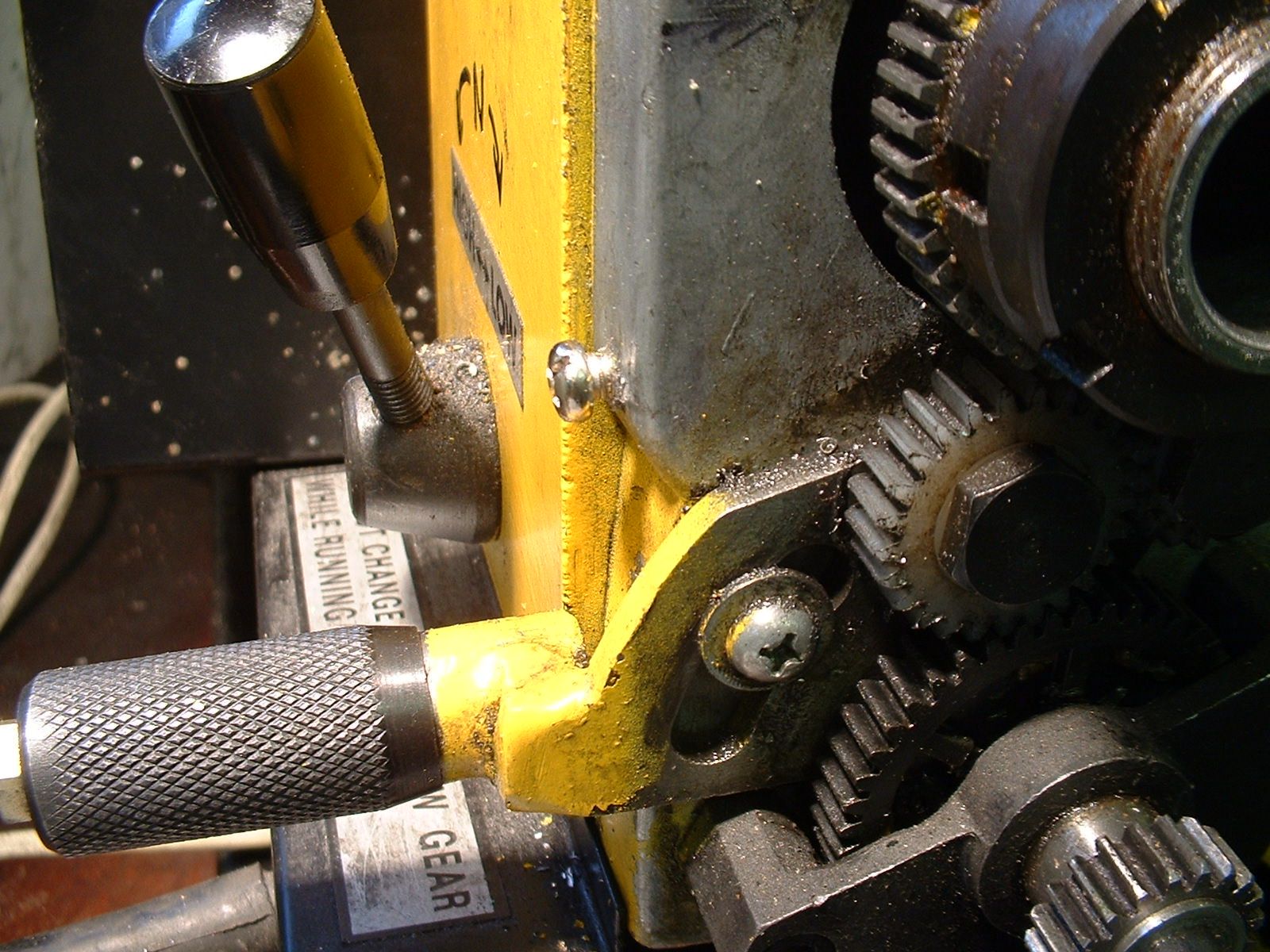

Remove the guard retaining screws and identify and mark locations for two fixing lugs. These should be just above the bottom of the vertical sides of the reverse gear mounting plate. Carefully drill the guard tapping size for M4. Replace the guard and, using a hand drill, spot through to the reversing gear mounting plate. Remove the gear plate then drill and tap an M4 hole on each side of the plate at the spotted marks. Fit two round headed screws (they do have a use!) in place, using retainer and leaving them 2mm from ‘home’.

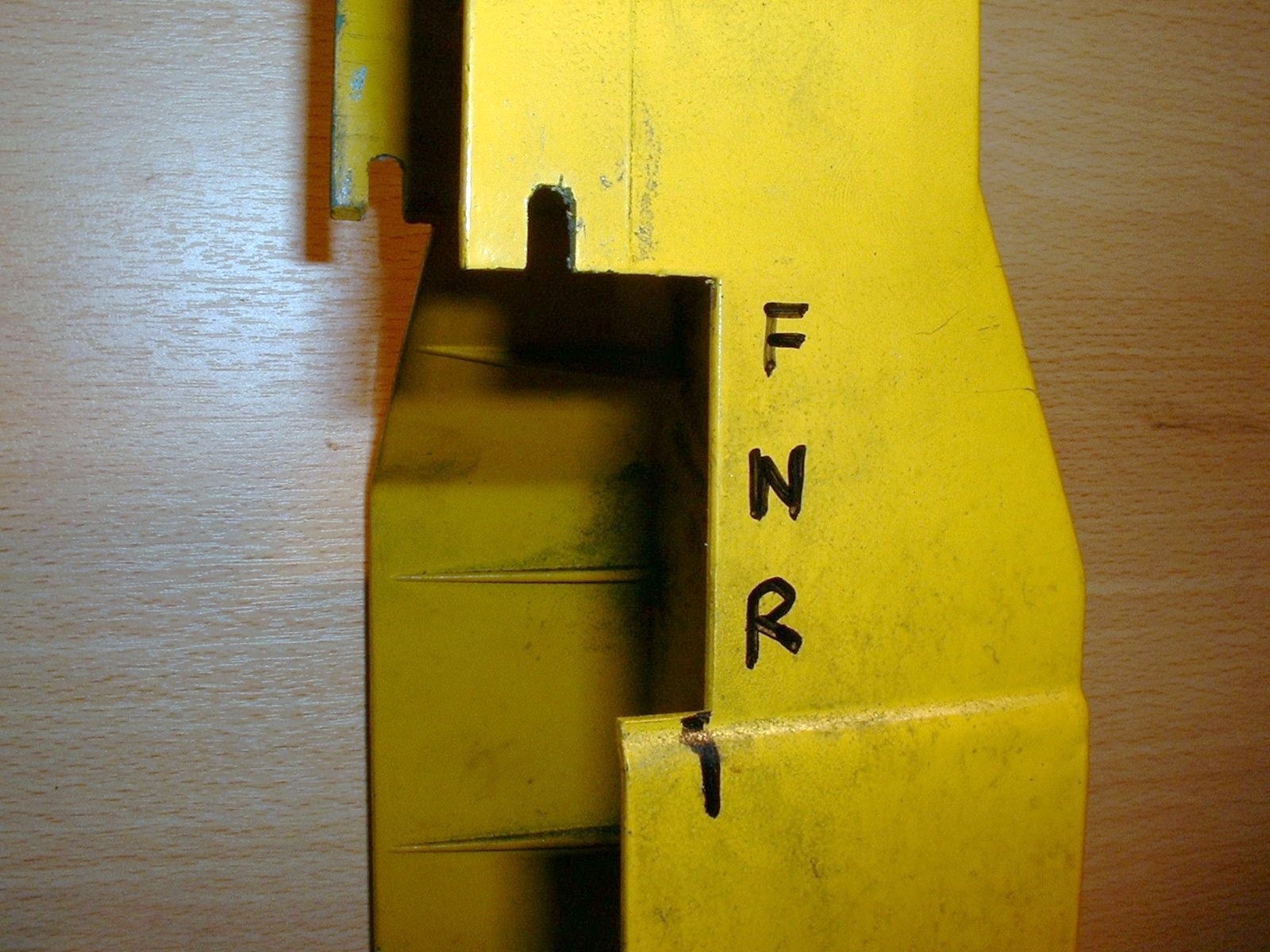

Now open the holes in the cover up to 4mm and with a razor saw or junior hacksaw, extend them into vertical slots, a shown in the photo. The letters stand for Forward, Neutral and Reverse with the tumbler gear lever.It now takes only a moment to remove the cover, with an up and out motion. Even with the largest changewheels fitted, there is no interference, and the guard is quite secure in normal use. An added bonus is that one of the existing mounting holes in the guard can be used to run a speed sensor cable into the guard, far from swarf and without any risk of fouling the gears.

While on the subject of mini-lathe change gears, it is unfortunately possible to strip the keyway if the leadscrew is jammed. This happened to me. I found I was able to save the day by boring out the gear oversize and fitting a ‘top hat’ steel sleeve from standard hex stock, slotted for the keyway. Without the flange, the sleeve would have been too flimsy, unless made so thick that the hub of the gear would have been weakened. I used two-pack epoxy to fix the sleeve in place, and the gear continues to give good service.